Engineering Clean

Tomorrow, Today

SaveEco Energy India delivers advanced industrial solutions that enhance operational efficiency while ensuring environmental compliance. As a trusted EPC Company, we engineer reliable pneumatic conveying systems, flue gas cleaning solutions, and waste heat recovery systems for India’s core industries.

European Technology. Indian Excellence. Global Standards.

Engineering Excellence.

Sustainable Innovation.

SaveEco Energy India Pvt Ltd is an EPC solutions and technology company specializing in critical industrial engineering solutions for energy efficiency and environmental protection. Headquartered in Pune, India, we provide end-to-end project management — from process design and detailed engineering to manufacturing, commissioning, and lifecycle support.

With over a decade of experience and strong European collaborations, SaveEco combines Swiss and German technology with Indian project execution strength, offering advanced systems that deliver measurable results in cement, steel, power, and mineral industries.

200+ successful project installations

Pan-India installation footprint

Long-term service agreements

Technology upgrade partnerships

Industry Verticals Served

Core

Solutions

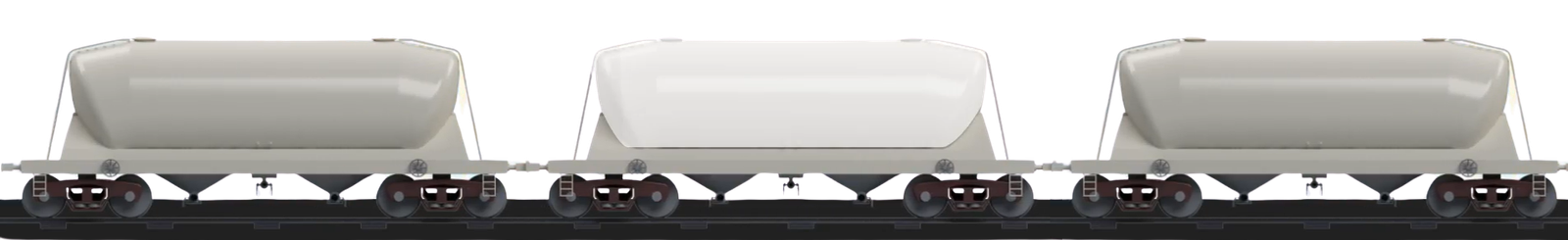

Engineered conveying solutions for cement, fly ash, minerals, and industrial powders using STAG AG’s proven dense-phase technology. Our systems ensure reliable material transport with minimal degradation and dust-free operation.

Key Applications:

- BTAP wagon unloading systems

- Truck and container discharge

- Plant internal conveying networks

- Silo loading and unloading

Technical Capabilities:

- Dense and dilute phase conveying

- Abrasive & fragile material handling

- Explosion-proof system design

- Energy-optimized operation

Engineered conveying solutions for cement, fly ash, minerals, and industrial powders using STAG AG’s proven dense-phase technology. Our systems ensure reliable material transport with minimal degradation and dust-free operation.

Key Applications:

- BTAP wagon unloading systems

- Truck and container discharge

- Plant internal conveying networks

- Silo loading and unloading

Technical Capabilities:

- Dense and dilute phase conveying

- Abrasive & fragile material handling

- Explosion-proof system design

- Energy-optimized operation

Waste Heat Recovery Systems

Intelligent Energy Recovery

Engineered conveying solutions for cement, fly ash, minerals, and industrial powders using STAG AG’s proven dense-phase technology. Our systems ensure reliable material transport with minimal degradation and dust-free operation.

Key Applications:

- BTAP wagon unloading systems

- Truck and container discharge

- Plant internal conveying networks

- Silo loading and unloading

Technical Capabilities:

- Dense and dilute phase conveying

- Abrasive & fragile material handling

- Explosion-proof system design

- Energy-optimized operation

Technology

Partnerships

R&R Beth GmbH (Germany)

"Flue Gas Cleaning Excellence Since 1887"

- Partnership: 50:50 Joint Venture

- Heritage: 130+ years of industrial filtration innovation

- Technology: Patented bag filter and emission control systems

- Indian Presence: Local manufacturing with German quality standards

STAG AG (Switzerland)

"Bulk Handling Technology Leaders"

- Partnership: Technology Partner

- Expertise: Pneumatic conveying and bulk material transportation systems

- Global Reference: Extensive installation base across industries

- Adaptation: Systems engineered for Indian operating conditions

MillNest (India)

"Complete Powder & Process Engineering Capabilities"

MillNest – SaveEco’s food/agro division provides grinding, milling, and blending systems for spices, pharmaceuticals, and chemicals.

- Powder handling + filtration for <5 μm dust control (pharma-grade)

- Unified project execution (design → service)

- Cross-technology workflow

Trusted by

Industry Leaders Across India

delivering measurable improvements in efficiency, compliance, and sustainability.

Featured Clients

The SaveEco Advantage

Reliability, Technology, Partnership

01

Single-Point EPC Responsibility

End-to-end project execution from concept to commissioning with unified accountability

02

European Technology Access

Proven solutions from industry-leading technology partners with global track records

03

Proven Project Experience

200+ successful installations across multiple industries with demonstrated operational performance

04

Technical

Expertise

120+ engineering professionals with deep domain knowledge and application experience

05

Manufacturing Excellence

State-of-the-art manufacturing facility in Pune ensuring precision fabrication and quality control

06

Lifecycle

Support

Comprehensive maintenance and service programs for sustained operational excellence

Solutions That Drive

Performance and Reduce Impact

Benefit from comprehensive, personal consultation and individually tailored solutions that prioritize energy-efficient, process-optimized design. We seamlessly integrate your company-specific requirements, ensure strict compliance with modern standards, and deliver precise static calculations for structural integrity.

Streamline your production and supply chain with RR-Bethfilter’s integrated Manufacturing & Logistics solutions—engineered for seamless operations, cost efficiency, and scalable growth. Leverage our precision-driven methodologies, compliance-focused frameworks, and bespoke strategies to boost productivity, minimize downtime, and achieve sustainable competitive advantage.

Saveeco delivers turnkey installation services and precision commissioning to ensure seamless system integration, performance optimization, and operational readiness—prioritizing safety, reliability, and efficiency from deployment through operation.

Saveeco delivers comprehensive preventive inspection and maintenance, performed by experienced in‑house service personnel who provide on‑site training for operating staff. With an extensive wear‑part and spare‑parts inventory, airflow measurements, ventilation audits, and retrofit modifications, we ensure optimal performance, regulatory compliance, and cost‑effective long‑term operation.

Frequently Asked Questions

Dense phase conveying uses high pressure and low velocity to transport materials gently through pipelines, minimizing product degradation and pipeline wear. Our STAG AG technology ensures reliable handling of various bulk materials.

R&R Beth's patented bag filter technology, developed since 1887, provides superior cleaning efficiency, longer filter life, and reliable emission control performance across diverse industrial applications.

Waste heat recovery systems capture thermal energy from process exhausts and convert it into usable power or heat, reducing external energy requirements by 10-30% and improving overall plant efficiency.

.

We serve cement, steel, power generation, mining, chemical processing, and food industries with specialized solutions for each sector's unique requirements.

Yes, we offer comprehensive lifecycle support including preventive maintenance programs, spare parts availability, retrofitting services, and 24/7 technical assistance.

Our approach combines waste heat recovery, advanced air filtration, and optimized pneumatic conveying systems to reduce emissions, cut energy losses, and improve plant efficiency. These sustainable solutions in energy & environment help industries meet compliance, lower operational costs, and move toward long-term environmental responsibility without compromising production performance.

Industries with high-temperature combustion or mineral processing—like cement, steel, power, petrochemical, and waste-to-energy—depend on Flue Gas Cleaning Solutions to meet emission norms, control SOx/NOx, and reduce particulate discharge in line with regulatory mandates.