Clean Air Solutions for Industrial Processes

Overview

Through our 50:50 joint venture with R&R Beth GmbH (www.rr-bethfilter.com), SaveEco Energy brings over 130 years of German filtration expertise to Indian industries. This partnership delivers world-class emission control performance with cost-effective implementation and ongoing support.

Our flue gas cleaning systems are designed to meet and exceed the most stringent regulatory requirements while optimizing operational performance. Every system is engineered considering dust characteristics, gas volumes, temperature profiles, and future expansion possibilities.

Bag Filters

Electrostatic Precipitators

Dry/Wet Scrubbers

Cyclones & Multi-Clones

Our Product Range

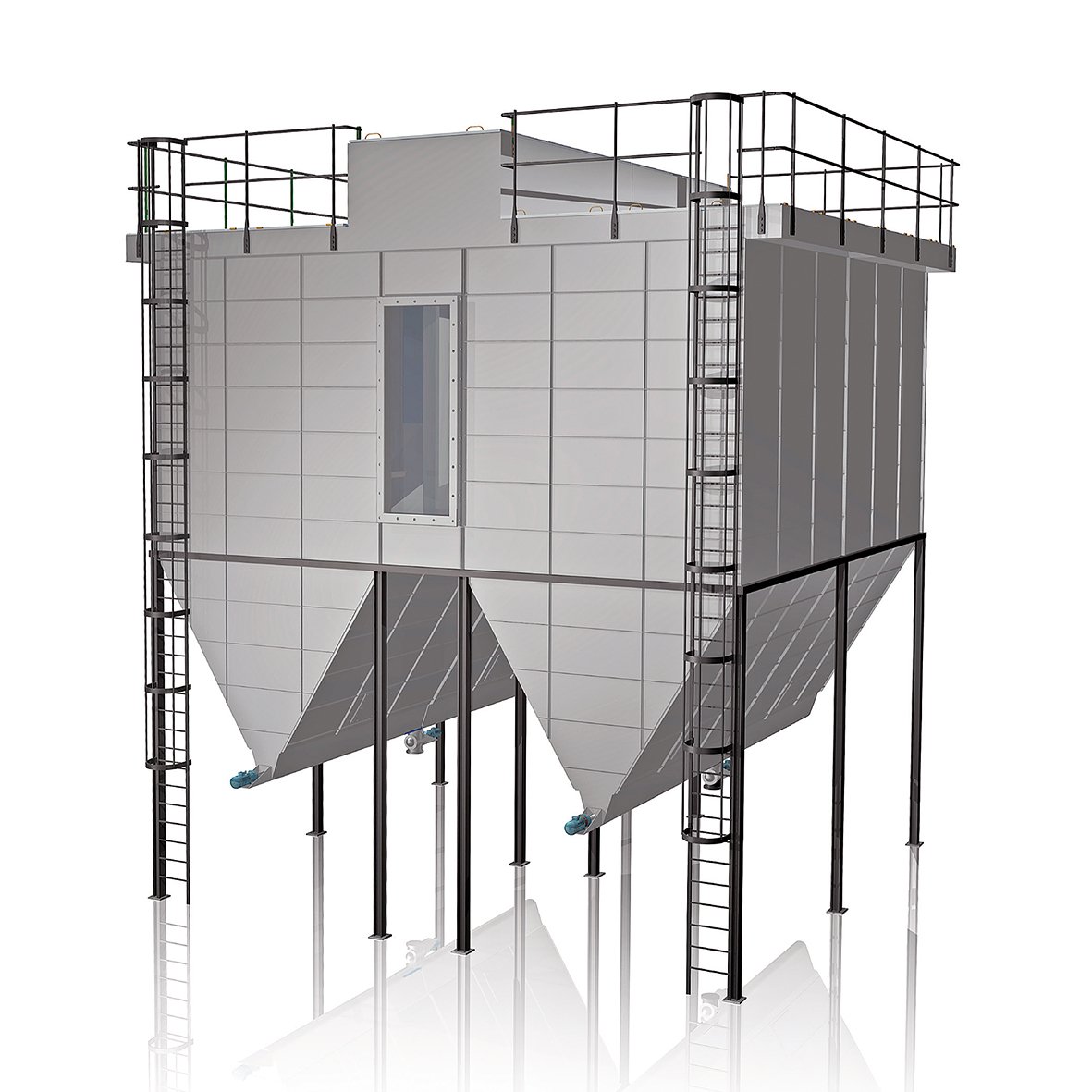

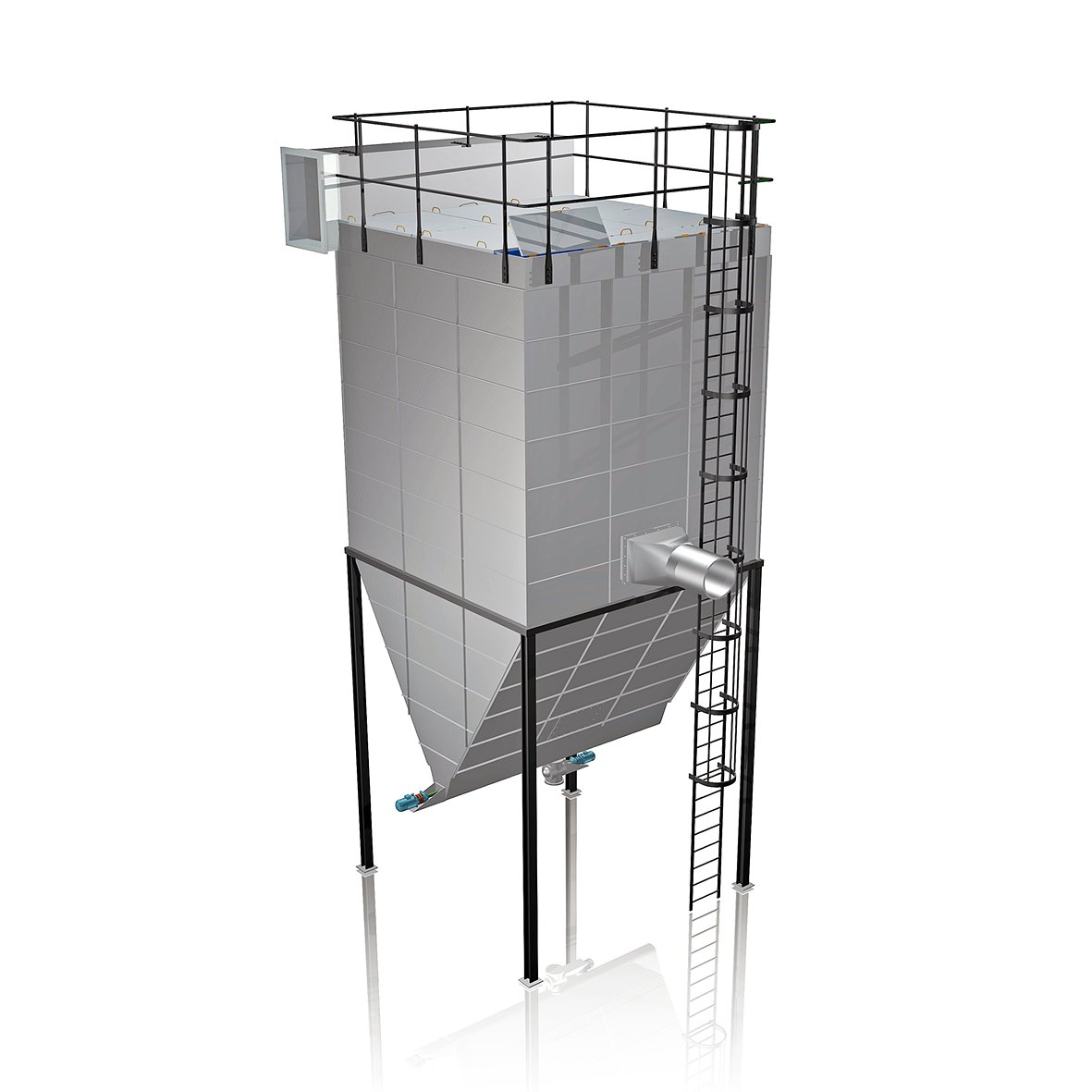

Bag Filters: High-Efficiency, Modular Designs for Continuous Operation

Pulse-Jet Bag Filter Systems

R&R Beth’s proprietary cleaning mechanism ensures consistent performance with minimal compressed air consumption. Our modular construction allows capacity expansion without production disruption.

- Technology Features: Patented filter media, optimized cleaning cycles, low pressure drop design

- Performance: >99.9% efficiency for particles above 1 micron

- Operating Range: Up to 260°C with specialized media

- Applications: Cement mills, power plants, steel furnaces, chemical processes

Reverse-Air Bag Filters

Gentle cleaning action ideal for hygroscopic and sticky dust applications with lower pressure drop for energy-efficient operation.

- Design Benefits: Extended bag life, online maintenance capability

- Special Features: Explosion-proof designs, food-grade construction

- Efficiency: Consistent performance across varying loads

- Industries: Chemical plants, food processing, pharmaceuticals

Electrostatic Precipitators (ESPs): For High-Volume, High-Temperature Gas Streams

Highly efficient systems for collecting particulate matter with minimal pressure drop and energy consumption.

- Design Excellence: Rigid electrode systems, optimized rapping mechanisms, intelligent power control

- Performance: Up to 99.5% collection efficiency

- Temperature Range: Suitable for applications up to 400°C

- Applications: Power plants, cement kilns, metallurgical processes, waste incinerators

Dry/Wet Scrubbers: Ideal for Acidic and Corrosive Fumes

Dry Scrubber Systems

- Lime/sodium bicarbonate injection for acid gas neutralization

- No liquid waste generation, compact footprint

- 95% removal efficiency for HCl, SO₂, HF

- Integrated with bag filters for particulate control

Wet Scrubber Systems

- Packed tower and venturi designs for maximum contact

- Simultaneous particulate and gas removal

- Corrosion-resistant construction materials

- Integrated mist eliminators for clean stack emissions

Cyclones & Multi-Clones: As Pre-Cleaners for Reducing Particulate Load

Cost-effective primary separation reducing load on downstream equipment.

- Efficiency: 85-95% for particles >10 microns

- Design Features: Abrasion-resistant linings, optimized inlet geometry

- Integration: Seamless coupling with bag filters and ESPs

- Benefits: Reduced maintenance on primary collectors

Key Applications

Cement Industry

- Kiln and raw mill dedusting systems

- Clinker cooler exhaust treatment

- Coal mill explosion-proof installations

- Packing plant dust control solutions

Power Generation

- Coal-fired boiler flue gas treatment

- Ash handling system dedusting

- FGD system integration

- Biomass boiler applications

Steel & Metallurgy

- Blast furnace gas cleaning

- Sinter plant emission control

- Electric arc furnace dedusting

- Coke oven gas treatment

Chemical & Process

- Reactor vent gas treatment

- Dryer exhaust cleaning

- Catalyst recovery systems

- Acid mist elimination

Advantages

Superior Performance

- Consistent <20 mg/Nm³ outlet emissions

- Compliance with CPCB and international standards

- Handles varying process conditions

- Future-ready for tighter regulations

Technology Excellence

- R&R Beth proprietary filter designs

- German engineering standards

- Continuous technology upgrades

- Local manufacturing advantages

Operational Benefits

- Low pressure drop design

- Minimal compressed air usage

- Extended filter bag life

- Automated cleaning cycles

Cost Optimization

- Lower lifecycle costs

- Energy-efficient operation

- Reduced downtime

- Optimized consumables usage

Manufacturing & Execution

Local Manufacturing with German Standards

- Design validation by R&R Beth engineers

- Precision fabrication with CNC machinery

- Stage-wise quality control protocols

- Performance testing before dispatch

Turnkey Project Execution

- Comprehensive site assessment and analysis

- Detailed engineering with 3D modeling

- Professional installation and commissioning

- Performance guarantee testing

Frequently Asked Questions

About Flue Gas Cleaning, Bag Filters & ESP Systems in India

Our flue gas cleaning systems consistently achieve particulate emissions below 20 mg/Nm³, with some configurations reaching <10 mg/Nm³.

Bag filters offer higher efficiency (99.9%) for smaller volumes, while ESP is more economical for large gas volumes (>500,000 m³/hr).

Dry scrubbers use chemical reagents without water, producing no wastewater. Wet scrubbers use liquid solutions for higher removal efficiency but require wastewater treatment.

Cyclones & multi-clones use centrifugal force to separate larger particles (>10 microns) as pre-cleaners before bag filters or ESP.

Regular inspections, filter bag replacement (2-3 years), hopper cleaning, and periodic calibration of monitoring systems.